wholesale mesh screen factory,vibrating screen screen mesh

Benefits of Using Wholesale mesh screen Factory Products for Industrial Applications Wholesale mesh screen factory products are essential components in various industrial…

Benefits of Using Wholesale mesh screen Factory Products for Industrial Applications

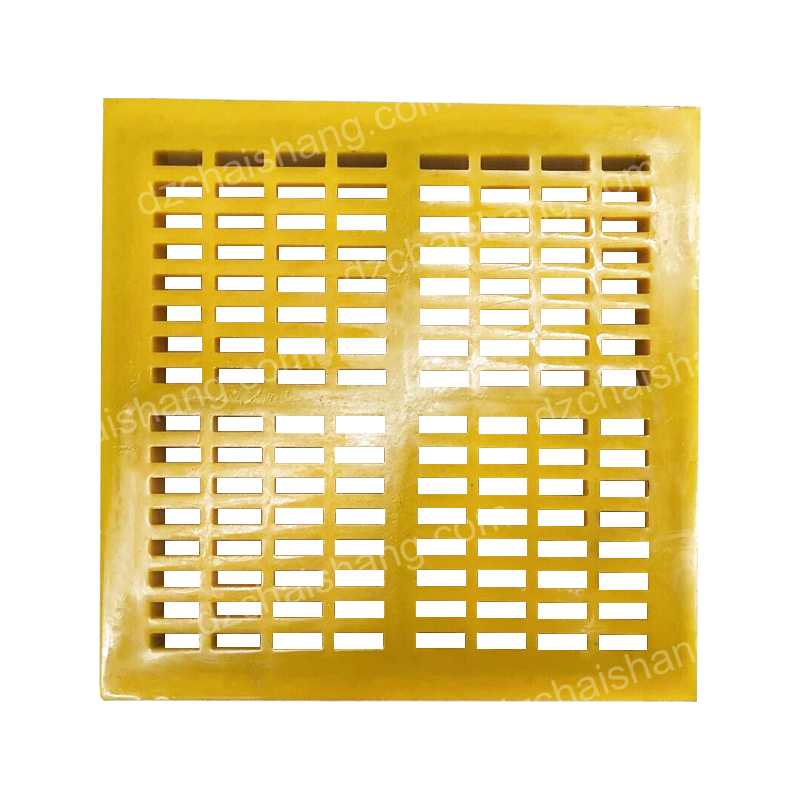

Wholesale mesh screen factory products are essential components in various industrial applications, providing a wide range of benefits that contribute to the efficiency and effectiveness of operations. One of the primary advantages of using wholesale mesh screen factory products is the high quality and durability they offer. These products are manufactured using premium materials and advanced technology, ensuring that they can withstand the rigors of industrial use and maintain their performance over time. In addition to their durability, wholesale mesh screen factory products are also highly customizable, allowing businesses to tailor the specifications of the screens to meet their specific needs. This flexibility enables companies to optimize their processes and achieve the desired results more effectively. Whether it’s a specific size, shape, or material, wholesale mesh screen factory products can be customized to fit the requirements of any industrial application. Another key benefit of using wholesale mesh screen factory products is their cost-effectiveness. By purchasing these products in bulk, businesses can take advantage of discounted prices and save money on their overall expenses. This cost savings can be significant, especially for companies that rely on mesh screens for their daily operations. Additionally, wholesale mesh screen factory products are designed to be long-lasting, reducing the need for frequent replacements and further lowering maintenance costs. Furthermore, wholesale mesh screen factory products are known for their high performance and efficiency. These screens are designed to provide precise and accurate screening, ensuring that materials are separated and sorted effectively. This level of performance is crucial in industrial applications where the quality of the end product is directly impacted by the screening process. By using wholesale mesh screen factory products, businesses can improve their overall productivity and output. Additionally, wholesale mesh screen factory products are versatile and can be used in a wide range of industries and applications. From mining and construction to agriculture and food processing, these screens are essential components in various sectors. Their versatility makes them a valuable investment for businesses looking to streamline their operations and enhance their efficiency. Moreover, wholesale mesh screen factory products are easy to install and maintain, reducing downtime and ensuring continuous operation. With proper care and maintenance, these screens can last for years, providing consistent performance and reliability. This ease of maintenance is particularly beneficial for businesses that rely on mesh screens for critical processes and cannot afford disruptions in their operations. In conclusion, wholesale mesh screen factory products offer a multitude of benefits for industrial applications. From their high quality and durability to their cost-effectiveness and efficiency, these screens are essential components that can help businesses optimize their processes and achieve their goals. By investing in wholesale mesh screen factory products, companies can improve their overall performance, reduce costs, and enhance their competitiveness in the market.How to Choose the Right vibrating screen screen mesh for Your Specific Needs

When it comes to choosing the right vibrating screen screen mesh for your specific needs, there are several factors to consider. The mesh screen is an essential component of a vibrating screen, as it determines the size and shape of the particles that can pass through the screen. This, in turn, affects the efficiency and effectiveness of the screening process. In addition to material, size, and shape, it’s also important to consider the weave pattern of the mesh screen when choosing a vibrating screen screen mesh. Mesh screens are available in a variety of weave patterns, including plain weave, twill weave, and Dutch weave. Each weave pattern has its own unique properties and advantages, so it’s important to choose the weave pattern that best suits your specific needs.

Plain weave mesh screens are simple and cost-effective, making them a popular choice for general-purpose screening applications. Twill weave mesh screens are stronger and more durable than plain weave screens, making them suitable for heavy-duty applications. Dutch weave mesh screens have a tight weave pattern that provides excellent filtration properties, making them ideal for applications where precise particle separation is required.

In conclusion, choosing the right vibrating screen screen mesh for your specific needs is essential for ensuring the efficiency and effectiveness of the screening process. By considering factors such as material, size, shape, and weave pattern, you can select a mesh screen that meets your requirements and delivers high-quality results. Whether you need a durable stainless steel mesh screen for a corrosive environment or a flexible polyurethane mesh screen for quick and easy replacement, there is a wide range of options available to suit your specific needs.

In addition to material, size, and shape, it’s also important to consider the weave pattern of the mesh screen when choosing a vibrating screen screen mesh. Mesh screens are available in a variety of weave patterns, including plain weave, twill weave, and Dutch weave. Each weave pattern has its own unique properties and advantages, so it’s important to choose the weave pattern that best suits your specific needs.

Plain weave mesh screens are simple and cost-effective, making them a popular choice for general-purpose screening applications. Twill weave mesh screens are stronger and more durable than plain weave screens, making them suitable for heavy-duty applications. Dutch weave mesh screens have a tight weave pattern that provides excellent filtration properties, making them ideal for applications where precise particle separation is required.

In conclusion, choosing the right vibrating screen screen mesh for your specific needs is essential for ensuring the efficiency and effectiveness of the screening process. By considering factors such as material, size, shape, and weave pattern, you can select a mesh screen that meets your requirements and delivers high-quality results. Whether you need a durable stainless steel mesh screen for a corrosive environment or a flexible polyurethane mesh screen for quick and easy replacement, there is a wide range of options available to suit your specific needs.